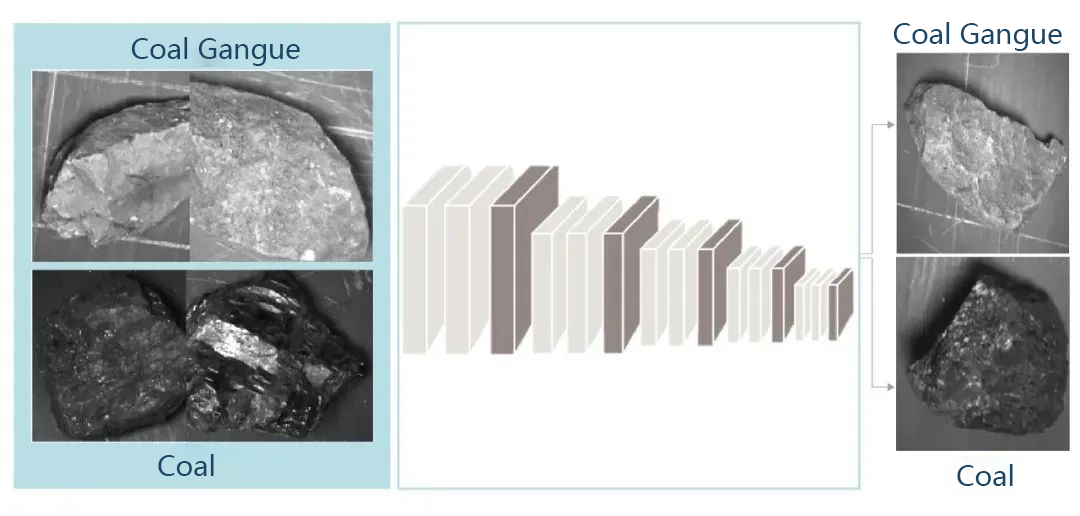

Coal gangue, a solid waste generated during coal mining and washing, accounts for approximately 15% of total coal production. As a hard black-gray rock with low carbon content and calorific value, its sulfide escape will pollute the surrounding farmland, water sources and even the atmosphere. Hense, it is of great significance to separate the coal and coal gangue in the raw coal by technical methods in the previous stage to improve the combustion efficiency and lower the emission pollution.

Current Methods and Limitations For Coal Gangue Recognition and Sorting

The purification is different from the quality inspection of parts in industrial production. The appearance of coal and coal gangue is similar and difficult to detect. Various impurities in the mined raw coal, such as leaves and garbage, can also be blended into the coal. At present, coal gangue sorting mainly includes three approaches: wet separation, dry separation and manual sorting.

Wet Separation: The wet separation method mainly includes dense medium separation (DMS) and jigging methods. It features that the raw coal is put into the solution by using the different densities of coal and gangue, so as to realize the layered separation of coal and gangue. However, as the equipment used is huge and its sorting process is complicated, which leads to relatively low efficiency. More importantly, the use of wet separation will still pollute the environment.

Dry Separation: The dry separation method includes drum crushing by using the different strengths of coal and gangue and visible light identification and sorting by using the different light transmittance of coal and gangue. Remarkably, the former destroys the shape of coal block, the sorting rate is poor and the equipment is huge, while the latter is expensive and the sorting efficiency is low.

Manual Sorting: Manual sorting is to separate the gangue from the lump coal , or separate the coal from the gangue manually. The sorting methods are different according to the coal quality characteristics and process flow. The manual sorting method is simple, but when the coal output is large, it will seriously affect the quality of gangue (coal preparation). The labor intensity of workers is also very high while the sorting efficiency is very low. From the perspective of labor welfare, the working condition is also too bad for their health.

How SmartMore Can Help You Develop Your Recognition and Sorting System

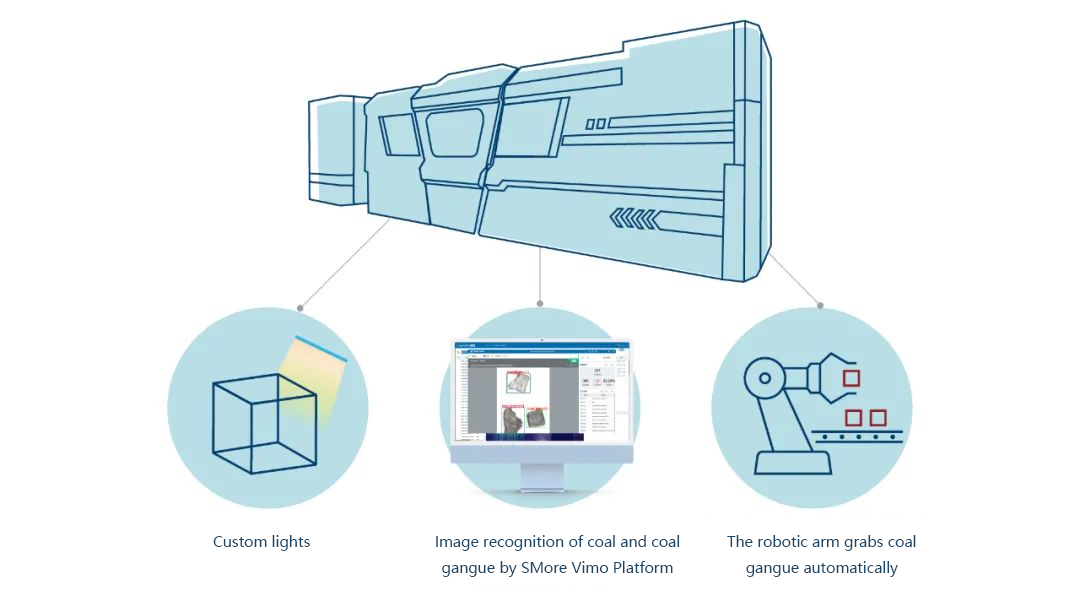

As mentioned above, it is challenging to classify coal gangue precisely only through conventional methods and vital to utilize the cobot arm to instantly complete the sorting action on the production line to achieve coal purification. Thus, the purification process requires a combination of visual inspection technology with lighting modules and cobot arms.

Luckily, with SmartMore, a leading machine vision company for industrial automation, we provide you with the inspection software SMore ViMo and developed a specific vision system for coal gangue automatic recognition. The entire coal gangue sorting process will be automatically completed with the cobot arm integrated into the hardware equipment. Your system will experience ultra-fast and accurate grabbing even in hygiene, humid or harsh environments!

Specialized in intelligent manufacturing and digitalization for 20 years, SmartMore offers high-quality certified vision products customized for clients, including industrial cameras, FA lenses, IPC, and lights, high-speed automatic cobot arm, providing a complete solution for Coal Gangue recognition and sorting. If you are interested in obtaining our smart solutions, please click here to learn more!

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent